Parts / Accessories

Hydropac machines require minimum maintenance and servicing, here is where you will find the spare parts that you might need, manifold units and pouch compactors to reduce used pouches into easily handled mesh bags for disposal or re-cycling.

Hydropac is a complete system and you will find all the optional bits of kit that makes this method of providing your animals drinking water the easiest and most reliable on the market.

Hydropac™ Enrichment Adapter

The Hydropac™ Enrichment Adapter is designed to use Hydropac™ Pouches in different cage types. Place the Adapter inside the cage and the animals can easily reach the Sterile Disposable Valve™. The lid of the cage closes the top of the adapter, therefore the animals can’t come in direct contact with the Pouch.

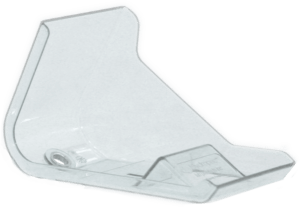

Wire Bar Lid Adapter

The Wire Bar Lid Adapter is a receptacle that allows a wide variety of wire bar lids to accept either a 384 ml or 236 ml water filled Hydropac™ Pouch and sterile Disposable Valve™. This design protects the pouch material from animal access. A stainless steel grommet secures the valve into place, while a self-centering rib positions the valve between lid wires.

Manifold Unit Filters

The Manifold Unit Filters offers superior flow rates and long service life. The Filters are made from asymmetric polysulfone membrane media, and have an absolute rating of greater than 99.9% efficiency. Four protective polypropylene filter cartridges house filter grades varying from 10 micron to 0.1 micron.

Filter Size :

10 micron

1.2 micron

0.2 micron

0.1 micron

Hydropac™ Tote Containers

Each Tote Container stores up to 30 water filled Hydropac™ Pouches, providing a convenient, compact and ergonomic method for managing large or small watering needs. Totes stack securely, nest efficiently when empty and are made from translucent polypropylene for easy visibility of contents. Totes include a two-flap interlocking cover attached with stainless steel hinges and reinforced tabs for optional locking. Filled pouches can be stored in Totes for extended periods while maintaining water quality–a convenient method for maintaining emergency supplies.

Silicon Patch

The Silicone Patch provides a quick and convenient method for sample withdrawal or injecting precise doses of liquid into Hydropac™ Pouches with a syringe. When pierced by a syringe needle, the material self-seals and remains sealed after removal of the needle. Each patch includes a FDA grade adhesive (outer ring) on one side. The centre area is free of adhesive, allowing a syringe to only penetrate the patch and pouch film materials. Apply multiple patches for multiple injections or withdrawals. Patches simply remain with the pouch for disposal.

Tote Transport Cart

The Tote Transport Carts efficiently transport Tote Containers filled with Hydropac™ Pouches throughout a facility and are available in two models. The compact design and high quality 15 cm casters (two with brakes) provide easy maneuverability. Adjustable side rails offer easy access for loading and unloading and help protect Totes during transit.

Pouch Conveyor

The Pouch Conveyor is a motorized incline conveyor that automates the process of collecting and dispensing Hydropac™ Pouches during production. Securely attached to the AWS-5000 Pouch Machine producing 1,800 pouches an hour (30 per minute), the Pouch Conveyor operates in combination with a Tote Conveyor and Tote Containers to help provide an ergonomic and highly efficient pouch production process. The design of the AWS-5000 Pouch Machine provides a power outlet for connecting the Pouch Conveyor. Synchronized with the Pouch Machine, the motor speed of the Pouch Conveyor provides efficient collection of the pouches. Operating in conjunction with the Pouch Machine, a built-in safety feature will automatically stop the Conveyor, in the event of an interruption to pouch production.

Tote Conveyor

The Tote Conveyor provides a height adjustable staging area for collecting filled Hydropac™ Pouches into Tote Containers. Designed to work in combination with the AWS- 5000 Pouch Machine and Pouch Conveyor, rollers on the Tote Conveyor create an ergonomic surface for the filling and staging of Tote Containers. With a production rate of 1800 pouches an hour, each Tote reaches its capacity of 30 pouches in one minute. Several Tote Containers can be staged on a single Conveyor before being moved onto a Tote Transfer Cart. Attach multiple Conveyors in sequence for extending a continuous platform as desired.

Film Roll Lift Unit

The Hydropac™ Film Roll Lift Unit lifts, transports and positions Hydroseal™ Pouch Film for easy loading onto the AWS-5000 Pouch Machine. The unit provides excellent stability and powerful electric lift operation. Rear casters feature a central foot operated braking system with directional locking or wheel locking. An on-board rechargeable battery powers the cordless electrical lift, and large casters provide easy mobility over a wide range of floor surfaces.